Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, nec tincidunt ante.

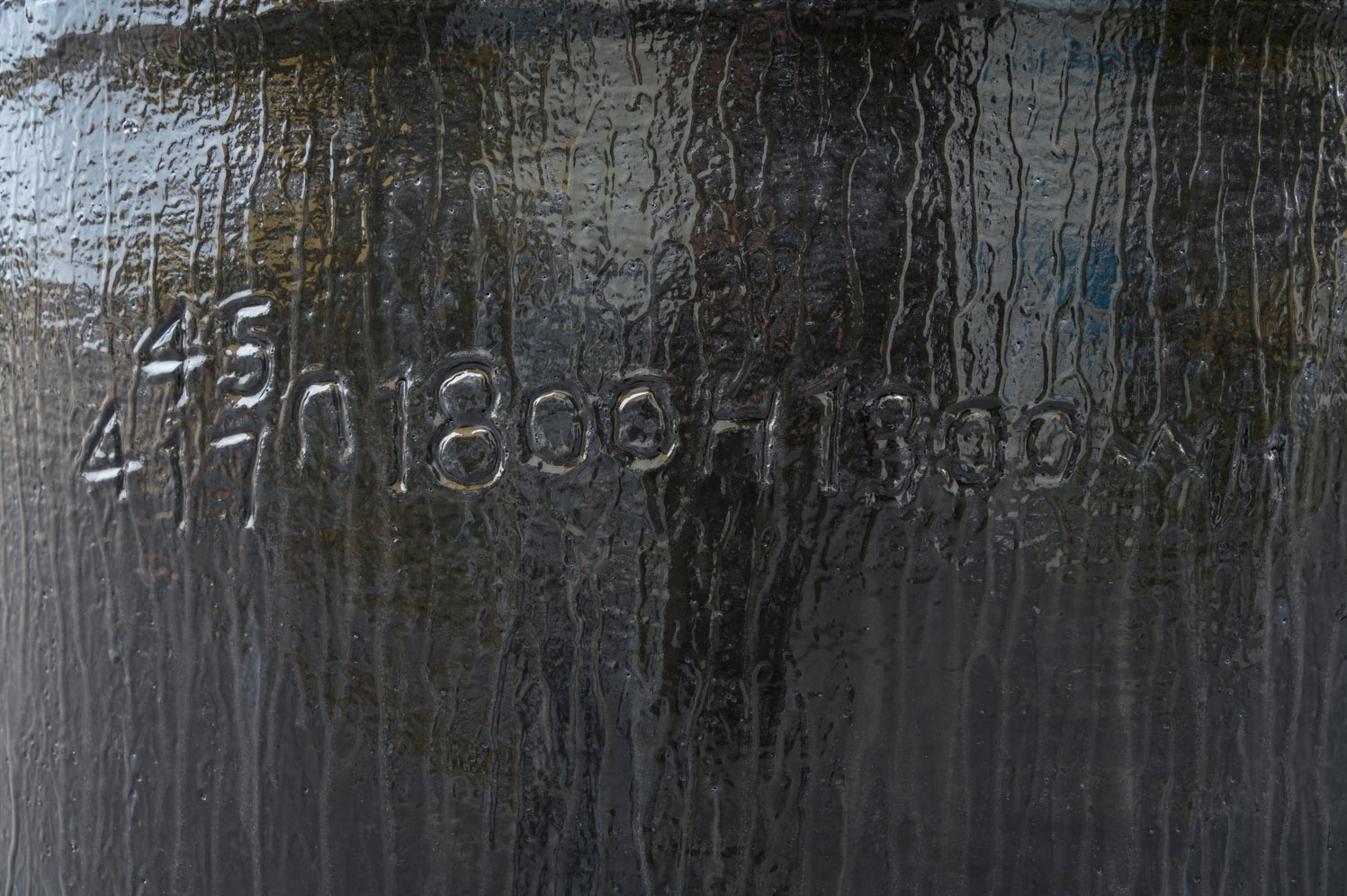

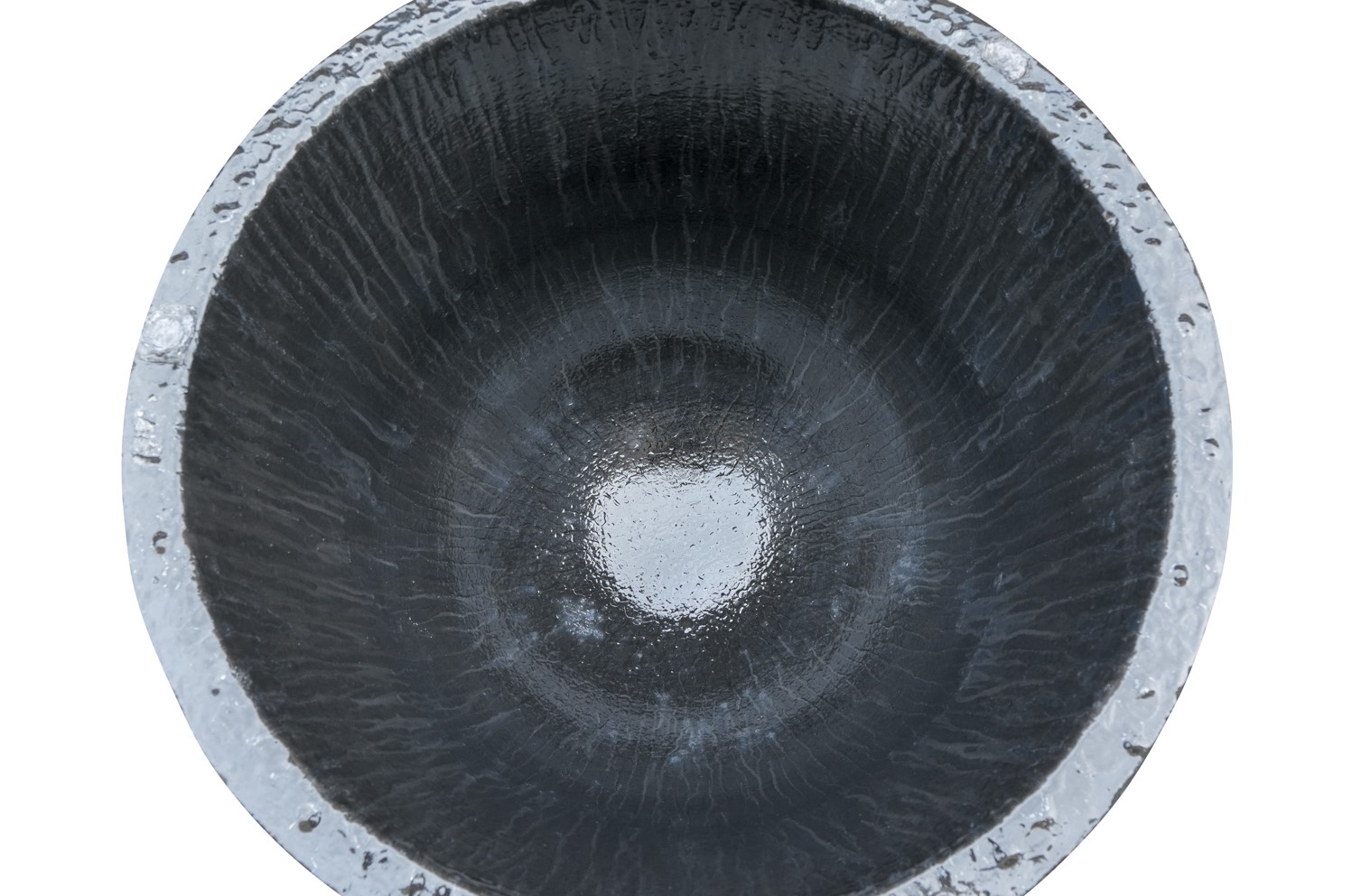

Crustulum liquefactum pro metallo non ferreo Fusio et Fusio

PROPRIETATES PRODUCTI

Celeris Liquefactio

Materia graphita altae conductivitatis thermalis efficientiam thermalem 30% auget, tempus liquefactionis insigniter minuens.

Resistentia Superior Ictus Thermalis

Technologia resina coniuncta calefactionem et refrigerationem celerem tolerat, onerationem directam sine fissuris permittens.

Durabilitas Eximia

Alta robur mechanicum impactibus physicis et erosioni chemicae resistit, ut diuturnior vita utilis sit.

SPECIFICATIONES TECHNICAE

| Graphitum / % | 41.49 |

| SiC / % | 45.16 |

| B/C / % | 4.85 |

| Al₂O₃ / % | 8.50 |

| Densitas massae / g·cm⁻³ | 2.20 |

| Porositas apparens / % | 10.8 |

| Vis conterendi/ MPa (25℃) | 28.4 |

| Modulus rupturae/ MPa (25℃) | 9.5 |

| Temperatura resistentiae ignis / ℃ | >1680 |

| Resistentia impetus thermalis / Tempora | centum |

| No | Modellum | H | OD | BD |

| RA100 | Centum # | 380 | 330 | 205 |

| RA200H400 | CLXXX# | quadringenti | quadringenti | 230 |

| RA200 | 200# | 450 | 410 | 230 |

| RA300 | 300# | 450 | 450 | 230 |

| RA350 | 349# | 590 | 460 | 230 |

| RA350H510 | 345# | 510 | 460 | 230 |

| RA400 | 400# | DC | 530 | CCCX |

| RA500 | 500# | DCCLX | 530 | CCCX |

| RA600 | 501# | DCC | 530 | CCCX |

| RA800 | 650# | DCCC | 570 | 330 |

| RR351 | 351# | DCCL | 420 | 230 |

FLUXUS PROCESSUS

1. Formulatio Praecisa

Graphite altae puritatis + carburum silicii premium + aglutinans proprium.

.

2. Pressio Isostatica

Densitas usque ad 2.2g/cm³ | Tolerantia crassitudinis parietis ±0.3m

.

3. Sinterizatio Altae Temperaturae

Recrystallizatio particularum SiC structuram reticulatam tridimensionalem formans

.

5.Rigorosa Inspectio Qualitatis

Numerus singularis vestigationis ad vestigationem totius cycli vitae

.

4. Augmentatio Superficiei

Tegumentum anti-oxidationis → resistentia corrosionis triplo aucta

.

VI.Involucrum Salutis

Stratum ictus absorbens + Obiex humiditatis + Involucrum firmatum

.

APPLICATIO PRODUCTI

Aptus plerisque metallis non ferreis

Aluminium liquefac

Cuprum liquefac

Aurum Liquefac

CUR NOS ELIGE

Quaestiones Frequentes

Q1: Num Tegmen Crucible sumptus energiae minuere potest?

A: Certe! Caloris iacturam minuit, energiae consumptionem usque ad triginta centesimas partes minuens.

Q2: Quae fornaces sunt compatibiles?

A: Versatile est—idoneum furnis inductionis, gaseosis, et electricis.

Q3: Estne graphitus et carburus silicii tutus temperaturis altis?

A: Ita. Stabilitas eius thermalis et chemica eam perfectam ad condiciones extremas reddit.

Q4: Quomodo fissuras crucibuli prohibere?

Numquam materiam frigidam in crucibulum calidum (ΔT max < 400°C) immitte.

Celeritas refrigerationis post liquefactionem < 200°C/hora.

Forcipes crucibuli dedicatos utere (vitans ictum mechanicum).

Q5Quomodo fissuras in crucibulo prohibere?

Numquam materiam frigidam in crucibulum calidum (ΔT max < 400°C) immitte.

Celeritas refrigerationis post liquefactionem < 200°C/hora.

Forcipes crucibuli dedicatos utere (vitans ictum mechanicum).

Q6Quae est minima quantitas ordinis (MOQ)?

Modela Standardia: 1 pars (exempla praesto sunt).

Designationes ConsuetudinariaeDecem partes (delineationes CAD requiruntur).

Q7Quod est tempus productionis?

⏳Res in promptuIntra horas quadraginta octo mittitur.

⏳Mandata Consuetudinaria: 15-25diesad productionem et viginti dies ad mucorem.

Q8Quomodo determinare possumus num crispum defecerit?

Fissurae > 5mm in pariete interno.

Profunditas penetrationis metalli > 2mm.

Deformatio > 3% (mutationem diametri exterioris metire).

Q9Praebetisne consilium de processu liquefactionis?

Curvae calefactionis pro variis metallis.

Calculator fluxus gasis inertis.

Documentationes videographicae de amovendis scoriis.

Studium Casus #1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, nec tincidunt ante.

Studium Casus #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, nec tincidunt ante.

Testimonia

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, nec tincidunt ante. Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis.

- Ioanna Doe

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, nec tincidunt ante. Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis. Nam luctus convallis turpis, sed suscipit nunc ullamcorper ut.

- Ioannes Doe